- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

SUCCESS STORY

Automated testing under extreme conditions

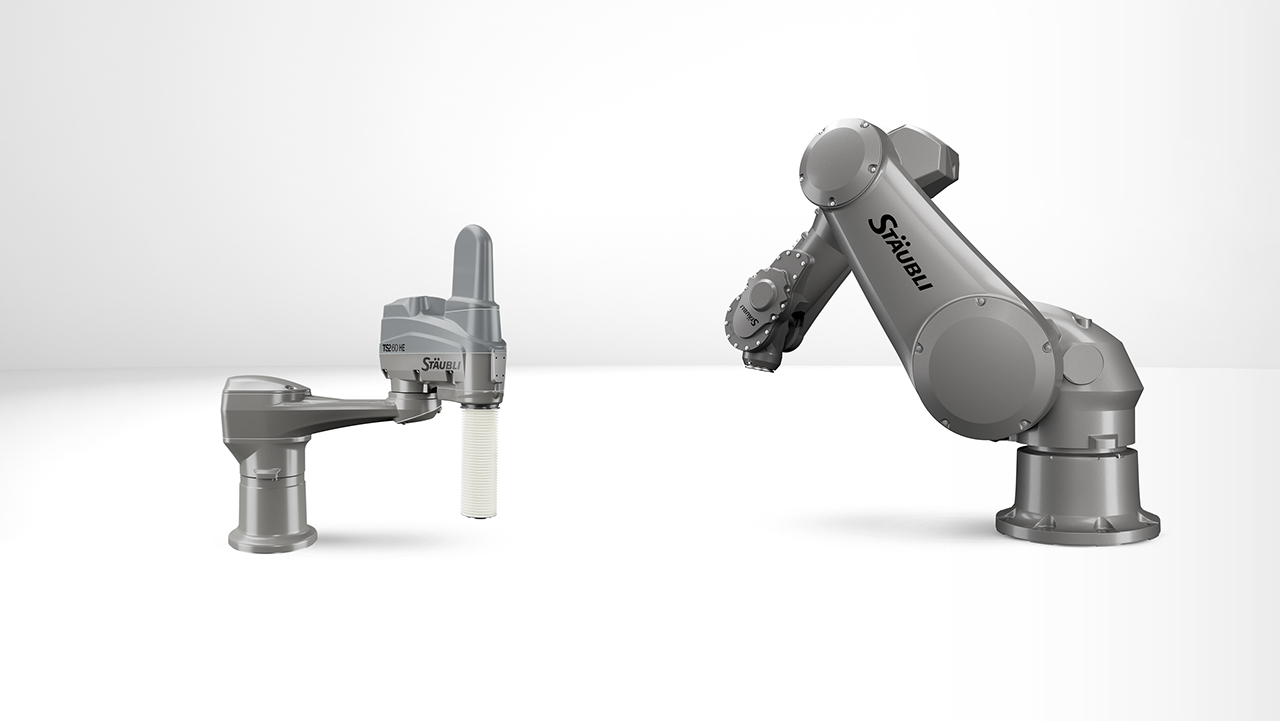

Quality checking touchscreens within a temperature range of -40 to +85 degrees Celsius places extreme demands on robotics. Now for the first time, a Stäubli six-axis machine is meeting this challenge without the use of a protective cover.

CUSTOMER BENEFITS

- Highly efficient testing of touchscreens

- Quality assurance taken to the next level

- No additional expense for protective robot cover

- User-friendly presentation of the test results

- Enhanced cost-effectiveness and flexibility

TASK

Quality checking of touchscreens in an environmental chamber

Quality checking touchscreens within a temperature range of -40 to +85 degrees Celsius places extreme demands on robotics. Now for the first time, a Stäubli six-axis machine is meeting this challenge without the use of a protective cover.

Touchscreens for use in cars have to undergo stringent endurance tests under extreme conditions before they can be approved for series production. Just how complex the test procedure is can be seen in the fully automated system designed and built by Kübrich Ingenieurgesellschaft of Priesendorf in Bavaria. Kübrich, a plant manufacturer specializing in quality testing, has built a robot cell that fully meets the stringent specifications laid down by Panasonic, namely the simulation of various haptic operating functions within a temperature window of minus 40 to plus 85 degrees Celsius and at a humidity level of up to 95 percent.

SOLUTION

The innovative test cell essentially comprises a high-performance environmental chamber in which the HE (Humid Environment) version of the Stäubli TX60L robot equipped with different operating fingers simulates the haptic operation of the touchscreens. The test cell and its components are controlled by Kübrich’s own Actere software.

High precision, superior dynamics and above all thermal robustness were the key criteria in the selection of this robot. “Irrespective of the fact that we have been integrating Stäubli robots into our environmental chamber test systems for many years now, there really was no viable alternative in the case of this application,” explains Christian Kübrich, CEO of the engineering company. “Because only a Stäubli robot with its proprietary drive technology is able to work under conditions of between -40 and +85 degrees Celsius at up to 95 percent humidity without a protective cover. And that’s exactly what we needed here.”

The tests can be carried out with different criteria for up to six different display types under changing climatic conditions in defined cycles.

CUSTOMER USAGE

The flexible system controller also allows the execution of different test programs for individual displays with single or multi-finger operation. The frequent pressing of certain positions on the screen as well as drag and swipe movements are simulated, together with exposure to perspiration and the wearing of gloves.

With 50 different test parameters per display under different thermal conditions and supply voltages, the checks quickly add up to an average of several thousand. The results are recorded by the evaluation software developed by Kübrich and presented in a user-friendly format.

This pioneering system sets new standards in display testing. The impressive performance of the Stäubli robot, which works reliably under these extreme climatic conditions without a protective cover, has facilitated the realization of this exceptionally efficient concept which is taking quality assurance to a new level of affordability and flexibility while at the same time optimizing measurement tolerances.